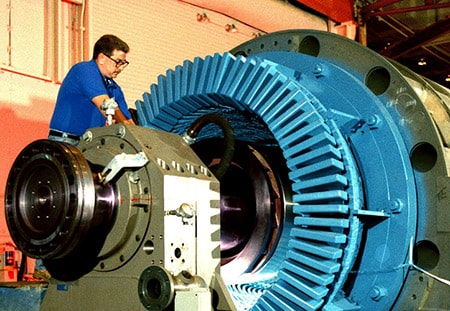

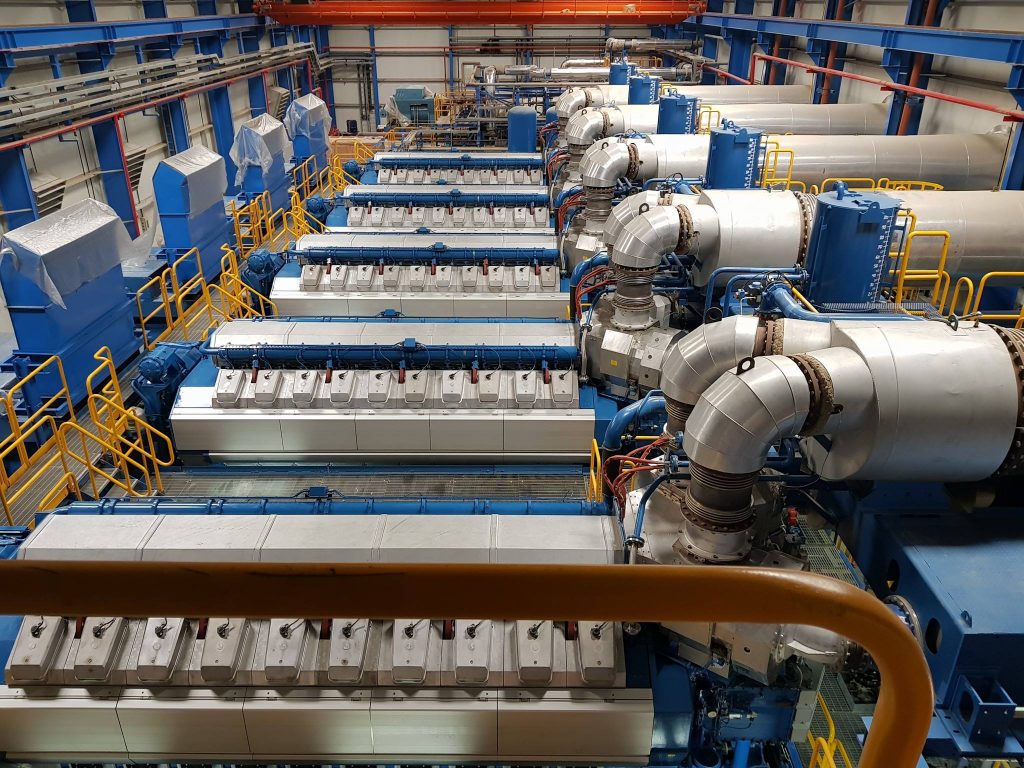

Generator condition assessment is an essential requirement of effective asset management programs, which are conducted to reduce forced outages due to unexpected failures or to identify causes of degraded performance. Accurate condition assessments of generators help utilities to invest their capital budgets wisely and to establish maintenance programs that address the most at-risk components of the machine.

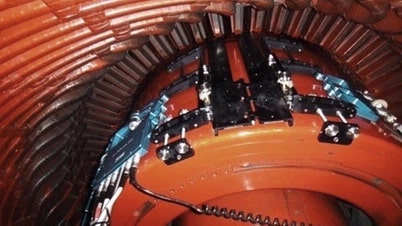

Many failure mechanisms can be detected early on by targeted visual inspections; hence, visual inspection is a key part of generator condition assessment studies. Commonly inspected components include stator and rotor winding and insulation systems, cores and frames, brush gear, and slip rings. Our generator specialists can provide a detailed visual inspection, supplemented with electrical tests to achieve a comprehensive condition assessment of your generators.

ZGL is experienced in a variety of diagnostic tests to evaluate generator condition. We provide a customized package tests for each machine, based on the operation and maintenance history, design, and needs of the specific generator.

Generator Testing:

- Visual Inspection

- Insulation Resistance (IR) / Polarization Index (PI)

- Dielectric Discharges Test

- Step Voltage Test

- Winding Resistance Test

- Power Factor / Tip up Test

- Partial Discharge

- AMT Pro (MBFDT)

- HV Main Bus Testing

- HV Neutral Bus Testing